Features & Characteristics

1. Main Functions

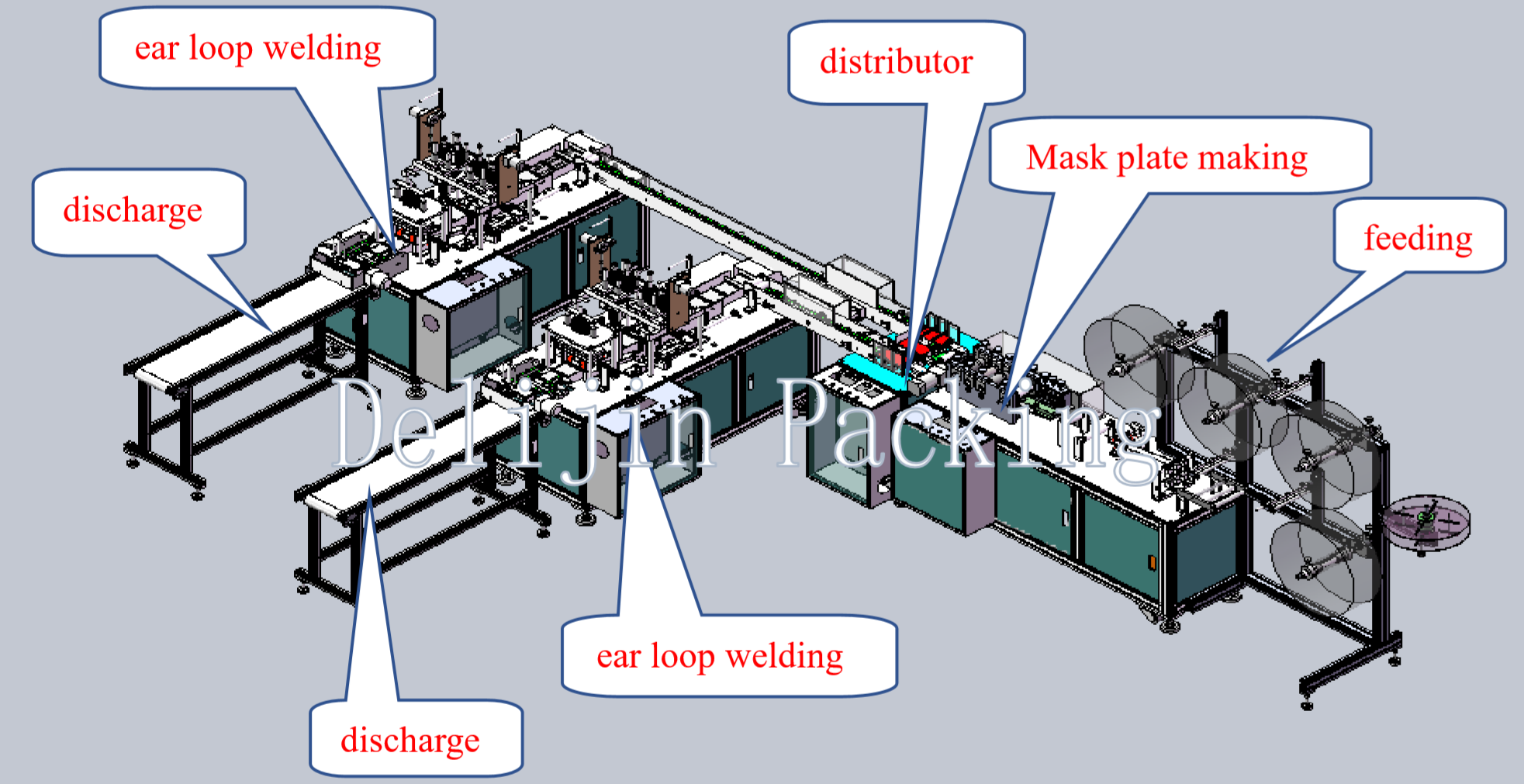

This machine is designed for producing one-time-use planar masks, which can improve the overall production efficiency, reduce production costs and improve product quality. The main functions of the equipment: mask folding, placement of metal nose clip, ultrasonic rolling, masks cutting off, ear loop welding, ear loop blinding, masks stacking.

2. Production Process

Non-woven and melt blown fabrics material feeding → Folding → Forming → Nose clip welding → Flanging → Ultrasonic edge sealing → Fixed-length cutting → Semi-finished product outputting → Distribution and Fixed-distance transmission (One cutting & Two welding) → Ear loop feeding/ ultrasonic welding→Ear looping blinding→Out putting and Stacking

3. Multi-function: automatic conveying, automatic feeding, automatic sealing, automatic countering.

lControl system:PLC control system; The mask body automatically transmitted to ear welding equipment, maximum limit artificial cost and with higher production capacity.

l Operation system: Touch screen show Chinese and English two kinds language, rich with help function and fault display function.

lClean and hygienic : The equipment goes from raw material to finished product output, automatic operation, reduce human touch masks in the production process, meet the industry testing standards.

l Once non-woven raw material in unwinding part use up, machine stop automatically.

4. Adopting advanced PLC computer programming control, servo motors controlled, detecting raw material with sensors.

5. Main parts:

1) Feeding device.

2) One set of mask plate making and cutting parts.

3) Two set of mask plate feeding parts.

4) Two set of ear loop welding parts.

5) Collected and discharge parts.

6. The machine adopt automatic ultrasonic ear belt welding system.

7. Easy to maintain, low noise.

8. Touch screen controlling, parameter adjusted in touch screen easily.

9. Electric sensors detecting, stop automatically when failure occur.

10. Capacity:50-110 pcs/min.

11. Comprehensive design, rigid frame, famous brand major components, this allows our machine work steadily & efficiently, and therefore this makes machine have long life.

12. The machine is suitable to make disposable flat masks.

13. Needed raw material:

1)Non-woven fabrics (inner and outer ply)

2)melt blown fabrics(medium ply)

3)nose clip

4)ear loop