D653 one/two layers roll bundling machine

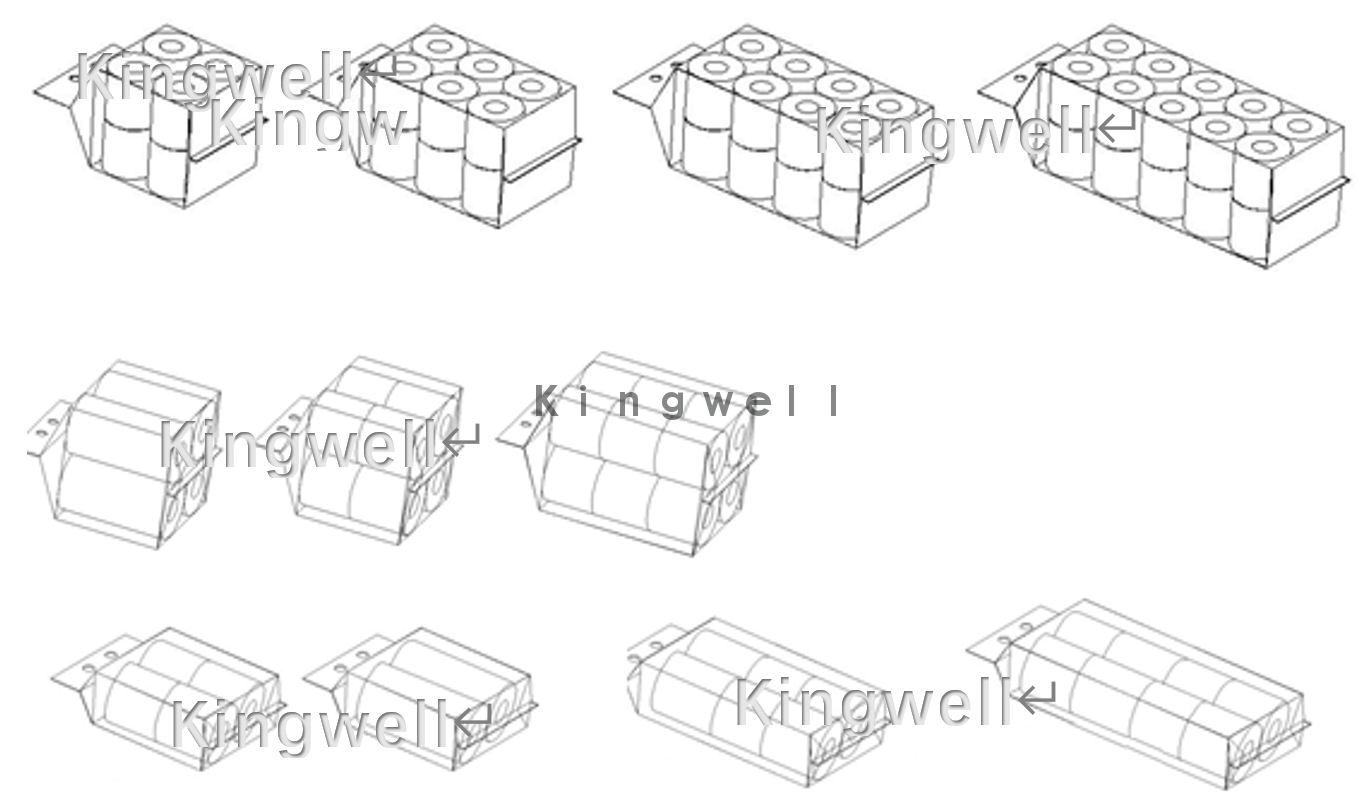

Packing style:

Application:

Can pack one or two layer of rolls. Applicable for packing:

1) 2,4,8,12,16,20,24 rolls, 2 layers bundling toilet rolls. Rolls can lie down or stand.

2) 2,4,8 bundling kitchen towels.

Features & Characteristics

1. Multi function: automatic conveying, single head operation, automatic feeding, automatic sealing, automatic countering.

2. Adopting the advanced PLC computer programming control and employing the liquid crystal text to display parameters, it is with simple set and water cooling control. Moreover, its temperature controlling is more precise so that heating wires and tapes with thermo stability can be protected more efficient. The machine use the servo motor to push the products to the bags, it causes to locating the products more accurately.

3. Packing and sealing are pretty and tidy. The machine can be operated with full-automation and semi-automation. The machine with conveyer can be connected with automatic toilet roll packing machine with conveyer. This allows the machine with high capacity and therefore to save the labor and reduce production cost.

4. Capacity: 8-12 bundling bags/min

5. Suitable for core or coreless toilet roll. The machine cannot proofread color code automatically.

6. Comprehensive design, rigid frame, and imported major component, this allows our machine work steadily& efficiently, and therefore this makes our machine have long life.

7. The machine is equipped with vacuum system which can take away the waste sealing film (offcut) automatically.

Principal capability and technical feature:

Model | D682 |

Capacity | 8-12 bags/min. |

Power source | 220 V,50 HZ |

Air pressure | 0. 6MPA |

Power | 2 KW |

Packing diameter | Diameter for single roll: Ø 90-120mm |

Packing height | Height for single roll: 100-150mm |

Maximum length of bundling | 700 mm |

Machine size | L5000×W1000×H1500mm |

Noise | ≤ 50dB |

Available for | toilet roll |

Packing pictures: